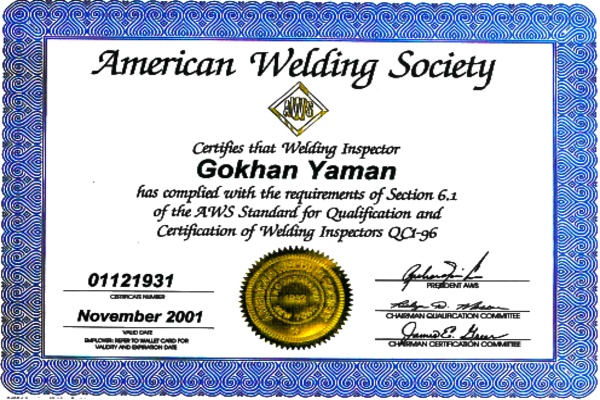

AWS- CWI Welding Inspector Certificate-2001 AWS-CWI Welding Inspector Certificate-2004

The Certified Welding Inspector certification is more than a rewarding career. It involves great responsibility and remarkable skill demonstration. The CWI® is widely recognized, both nationally and internationally, and successful companies have come to rely on this AWS certification when ensuring the highest level of quality workmanship.

The AWS-CWI Welding inspector course introduces a wide range of topics related to Welding Inspection, Quality and Safety and as listed below;

communicate effectively orally and written understand the fundamentals of SMAW, SAW, OFW, RW, GTAW, FCAW, GMAW, PAW, SW, ESW and thermal spraying, soldering, mechanical cutting, thermal cutting/gouging, brazing/braze welding understand the fundamentals of VT, MT, AET, UT, PT, ET, RT, LT, quality procedures and quality audits/surveillance understand the fundamentals of welding metallurgy understand welding symbols and drawings interpret drawings |

metal compliance verify filler metal storage/handling compliance verify inspection records compliance verify proper documentation compliance verify base material and filler metal compatibility certify documented results compliance verify procedure qualification records compliance verify welding procedure compliance verify NDE procedures compliance |

preparation compliance verify joint geometry compliance witness procedure qualification verify welding procedure qualification compliance review and approve welding procedures develop welding procedures |

performance qualification verify welder qualification compliance verify welder qualification records compliance request welder performance requalification |

qualification appropriateness verify production welding compliance verify personnel qualifications |

examination procedure compliance review examination results compliance develop visual inspection procedures (before, during, and after welding provide NDE inspection planning and scheduling (before, during, and after a project) review welding inspection reports verify implementation of nondestructive and destructive evaluation methods prepare visual inspection requirements prepare NDE requirements report investigation results of quality inspection disputes prepare destructive testing requirements |

compliance develop safety procedures and policies |

develop quality assurance plans prepare base material control requirements prepare weld consumable control requirements prepare audit and surveillance plans prepare documentation control requirements |

requirements review vendor proposal compliance prepare weld inspection bid specifications prepare purchase specifications determine vendor capacity and capability select vendor |

inspection training verify implementation of visual inspection training develop and provide a training program for the WI provide technical leadership for welding inspectors develop quality assurance training program verify implementation of quality assurance training provide guidance and direction to inspectors for maintaining and upgrading their individual qualifications |